Tel: +86-15238051165 Email: alice7136975@gmail.com

[Zhengzhou, Henan, China, May 28, 2025] — In a significant milestone for sustainable waste management solutions, the advanced **800-Type Dual-Shaft Shredder** has completed rigorous testing and is now ready for shipment to Mexico. Equipped with cutting-edge technology and robust performance, this industrial-grade shredder is poised to revolutionize recycling processes in the region, addressing challenges in plastic, metal, and tire waste disposal.

Key Features of the 800-Type Dual-Shaft Shredder

1. Powerful Performance:

- Dual 22 kW motors ensure high torque and low-speed operation (15–24 RPM), ideal for crushing hard materials like tires, metals, and thick plastics.

- Equipped with 40mm-thick alloy steel blades(SKD-11/D2 material) for exceptional durability and resistance to wear, extending service life to over 1,000 tons of material processed before maintenance.

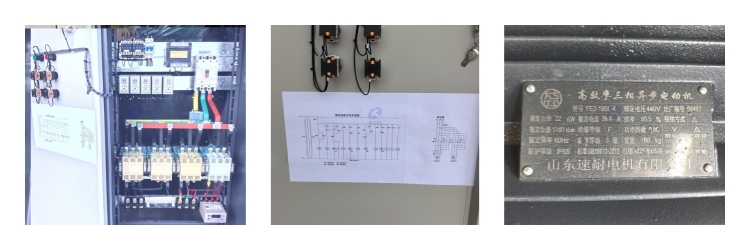

2. Intelligent Control System:

- PLC automation enables seamless operation, including auto-reverse functions to prevent jamming and overload protection.

- Adjustable blade configurations cater to diverse material outputs, ensuring precise particle sizes (8–30 mm).

3. Eco-Friendly Design:

- Low noise (<70 dB) and integrated dust suppression systems minimize environmental impact, aligning with global sustainability standards.

- Compact dimensions (3.2×1.3×1.95 m) and modular assembly simplify installation and logistics.

Successful Trial Run Highlights

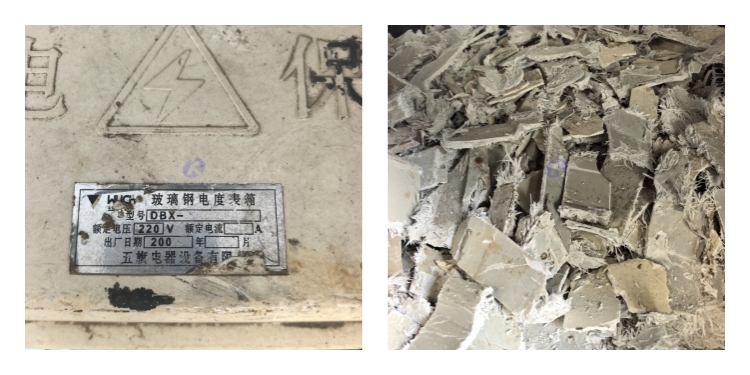

Prior to shipment, the shredder underwent a comprehensive electrical cabinet test with actual materials, including:

- Pre-shredded materials: Large plastic containers, rubber tires, and metal scraps.

- Post-shred results: Uniformly sized fragments ideal for recycling or compact transport (see attached images).

The trial confirmed a production capacity of 800–1200 kg/h, with seamless handling of mixed waste.

Applications & Market Potential in Mexico

The 800-Type shredder is engineered for versatility, making it suitable for:

- Plastic recycling: Crushing PET bottles, PVC pipes, and packaging materials.

- Metal processing: Shredding aluminum cans, automotive parts, and thin steel sheets.

- Tire disposal: Efficiently reducing truck and car tires into rubber chips for reuse.

Mexico’s growing emphasis on circular economy policies positions this equipment as a critical tool for waste management companies and recycling plants.

Commitment to Quality & Support

The manufacturer guarantees:

- Free technical training and on-site installation support.

- Long-term supply of wear-resistant parts, including blades and bearings.

- Compliance with international safety standards, including CE certification (pending client-specific requirements).

For media inquiries or partnership opportunities, contact:

Henan Kaidi Machinery Equipment Co., Ltd.

Email: Alice@hnkaidijx.com]

Phone: 86 15838196055

Contact: David

Phone: +86-15238051165

Tel: +86-0371-66488426

Email: alice7136975@gmail.com

Add: Mazhai Industrial Zone, Zhengzhou City, Henan Province